Report on Recent Situation of Feiyan Exhibition

Time:

2024-07-11 10:21

Source:

For many years specializing in nylon research and development, production and operation and consulting services of high-tech enterprises. Located in the famous town of socks-Datang Town, Zhuji City, Zhejiang Province. In the more than 20 years since the "swallow" was opened, we have worked tirelessly and continuously, gradually developing from the initial 2 reloading machines to a factory with 24 nylon filament POY screws, 8 DTY reloading machines and 45 yarn rewinding machines. Daily output, POY: 20 tons, DTY: 20 tons, colored nylon yarn: 6 tons, covered yarn: 3 tons, rubber thread: 3 tons. The company strictly implements ISO9001 international quality system standards and ISO14001 environmental management system standards, and products are strictly in accordance with OEKO-TEX standards.

News

Nylon 6 Filament: The Unsung Hero of Modern Manufacturing

Discover the versatile applications and benefits of Nylon 6 filament in the manufacturing world. Learn how this innovative material is shaping industries and what it means for the future.

Nylon 6 Filament Industry Dynamics

In recent years, the Nylon 6 Filament industry has continued to develop and has been favored by the market. The purpose of this article is to explore the latest developments and development direction of Nylon 6 Filament.

New material Nylon 6 Stretch Yarn emerging in textile industry

Nylon 6 Stretch Yarn is an innovative textile material with the advantages of strong, wear-resistant and good elasticity, which has attracted much attention in the textile industry.

Nylon 6 Stretch Yarn Market Continues to Grow, Industry Dynamics Analysis

In recent years, the Nylon 6 Stretch Yarn market has shown steady growth, and the degree of favor by consumers has continued to increase. This article will analyze the latest developments and future trends in the Nylon 6 Stretch Yarn industry.

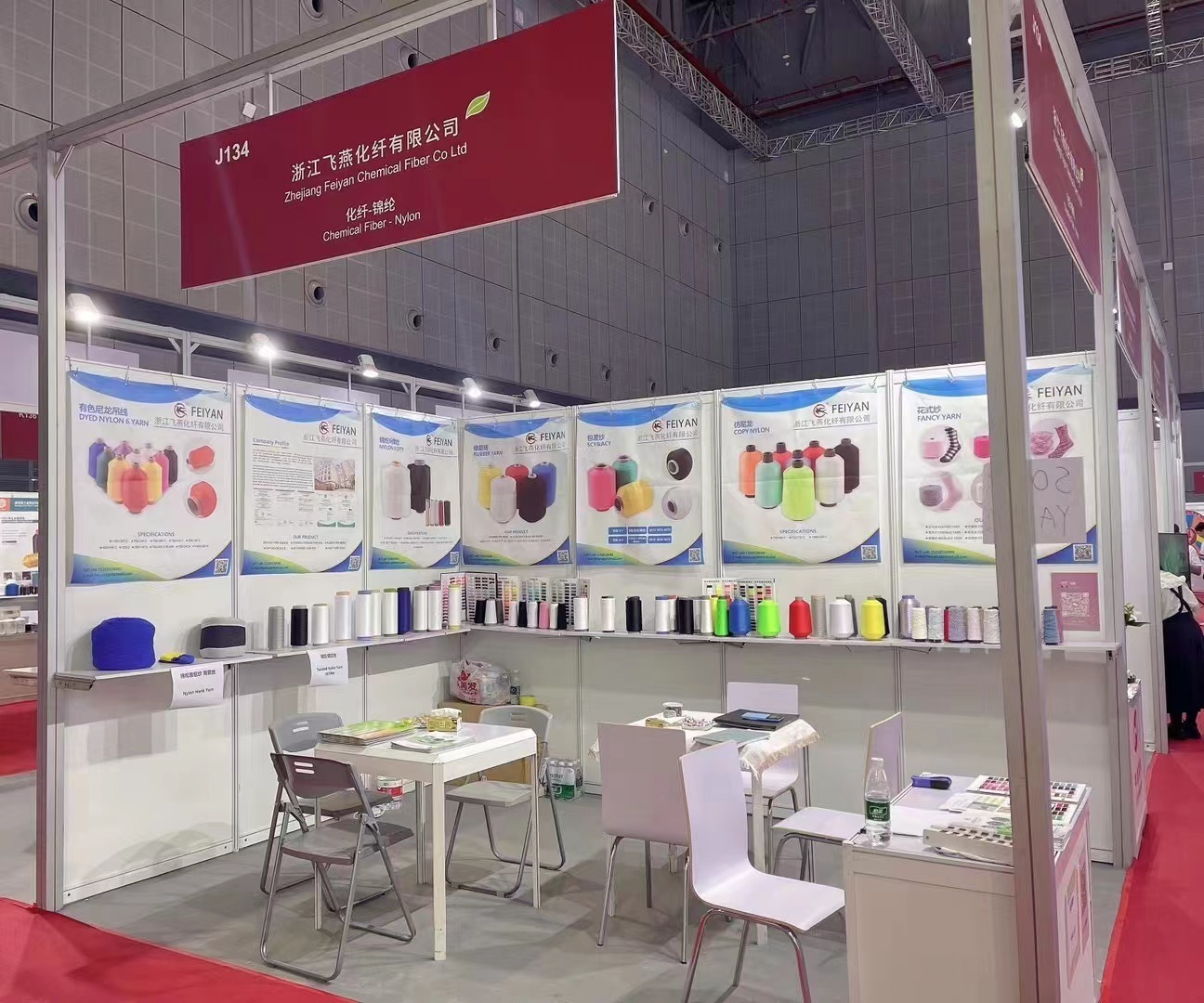

Zhejiang Feiyan Chemical Fiber Co., Ltd. will be unveiled at the Shanghai International Hosiery